SERVICES

WHAT WE DO

We provide a full customized wheel manufacturing service from start to finish. Whether you are a private label brand looking to expand your product range, an aftermarket wheel distributor servicing your region or a wholesale outlet, we have the skills and experience to provide you with the wheels you need. Our production methods cover cast, flow form / spin casting, monoblock and multi-piece forged manufacturing to suit the demands of the entire automotive wheel industry. With continuous quality control management, we pride ourselves on manufacturing premium wheel products for the international market.

OUR Services

We are a complete service provider for the automotive alloy wheel industry.

- Aftermarket Wheel Design

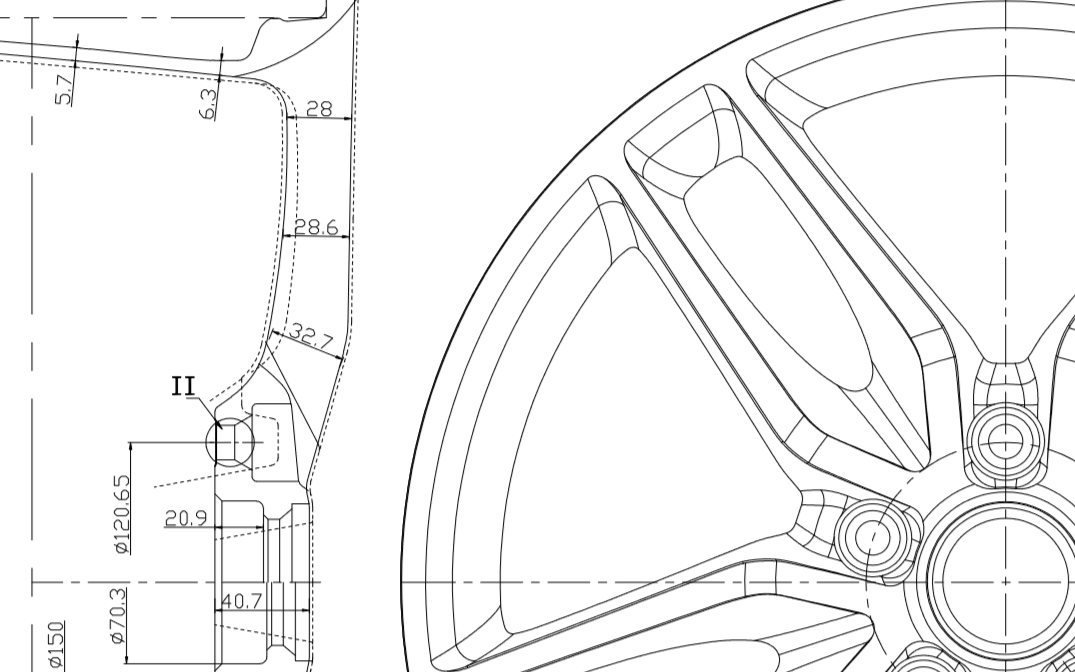

- New Tooling Development

- Aluminium Wheel Production

- Safety Testing

- Global Shipping

COMPLETE MANUFACTURING

Aluminium wheel production for the automotive sector. Passenger car, SUV / 4×4, flow formed and forged. 12″ wheels up to 30″ in diameter.

- Low Pressure Die Casting

- Dual Lip & Barrel Flow Forming

- 12" to 30" Sizes

- Lightweight Forged

- Concave, Staggered, Deep Lip, Undercut

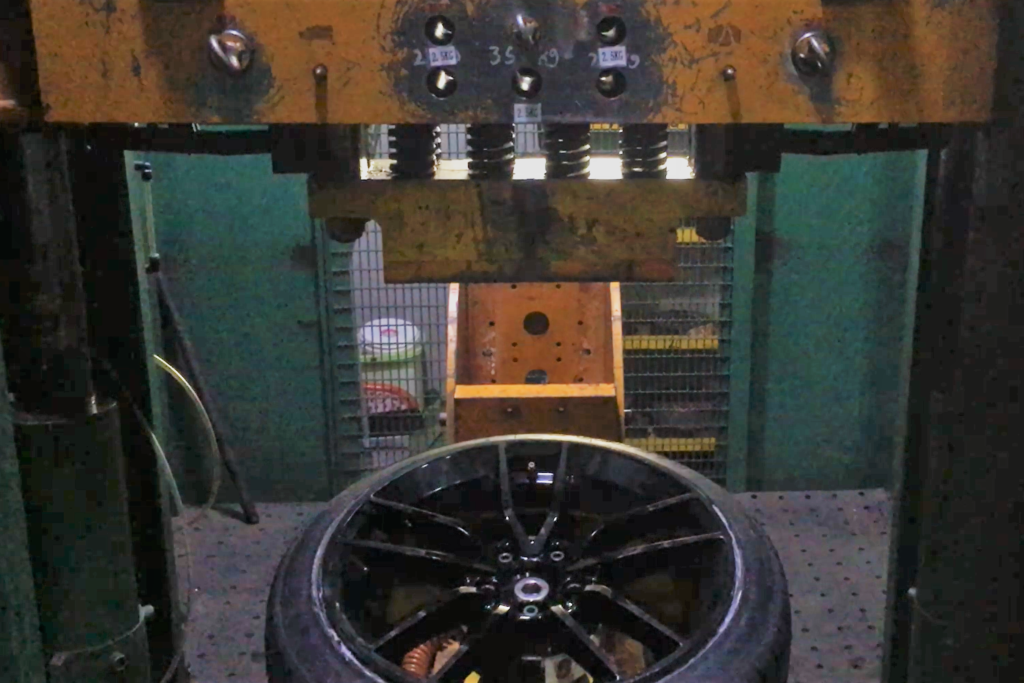

SAFETY TESTING

All of our production is implemented by ISO/TS16949 Quality Management Certification and meets or exceeds international quality standards appointed by JWL, VIA, TUV, DOT or TSE.

- Impact & Load Testing

- Radial & Cornering Fatigue

- Balance Testing

- Salt Spray Testing

finishing

Automated paint line offers full spectrum color finishing, with options for all finish requirements including –

- Diamond Cut CNC Machining

- Polishing

- Nickle Plated Chrome

- Milling

- Brushing

- PVD / Vacuum Chrome